Initiatives for security and safety

We will try new technologies with flexible thinking

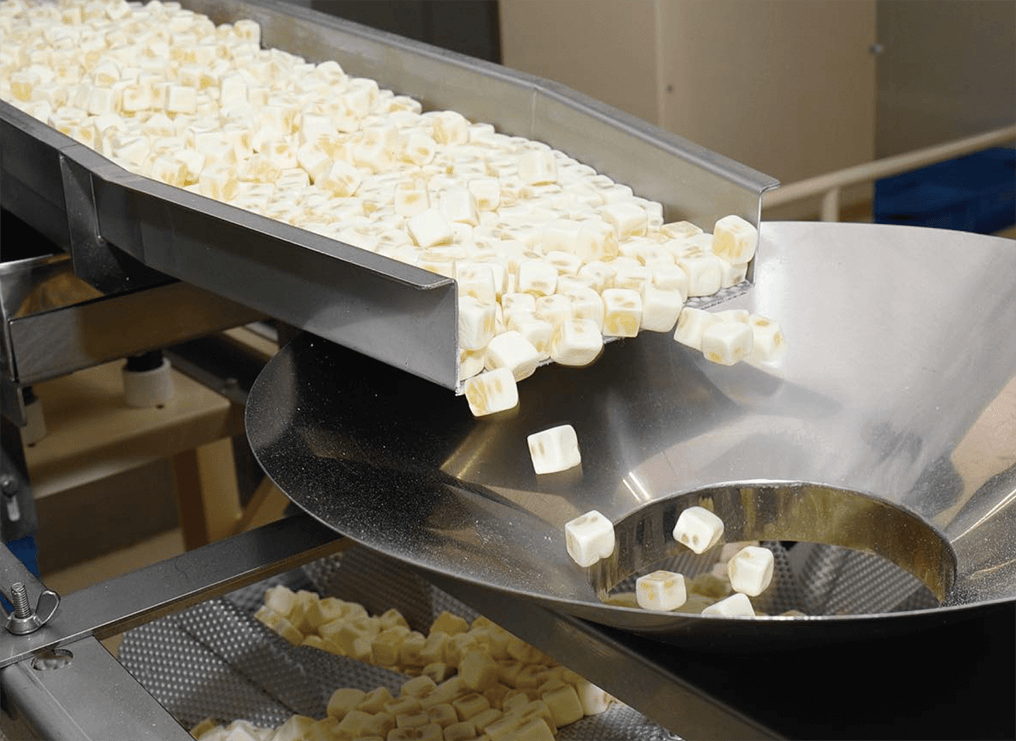

We, Kabaya, manufacture various kinds of confectionery at two locations.

At the headquarters, Okayama Factory, we manufacture products such as gummy, fizzy candy, chocolate, candy with toy, and at the other location, Kanto Factory and Kanto No.2 Factory (Ibaraki prefecture), we manufacture products such as chocolate and fizzy candy, candy with toy.

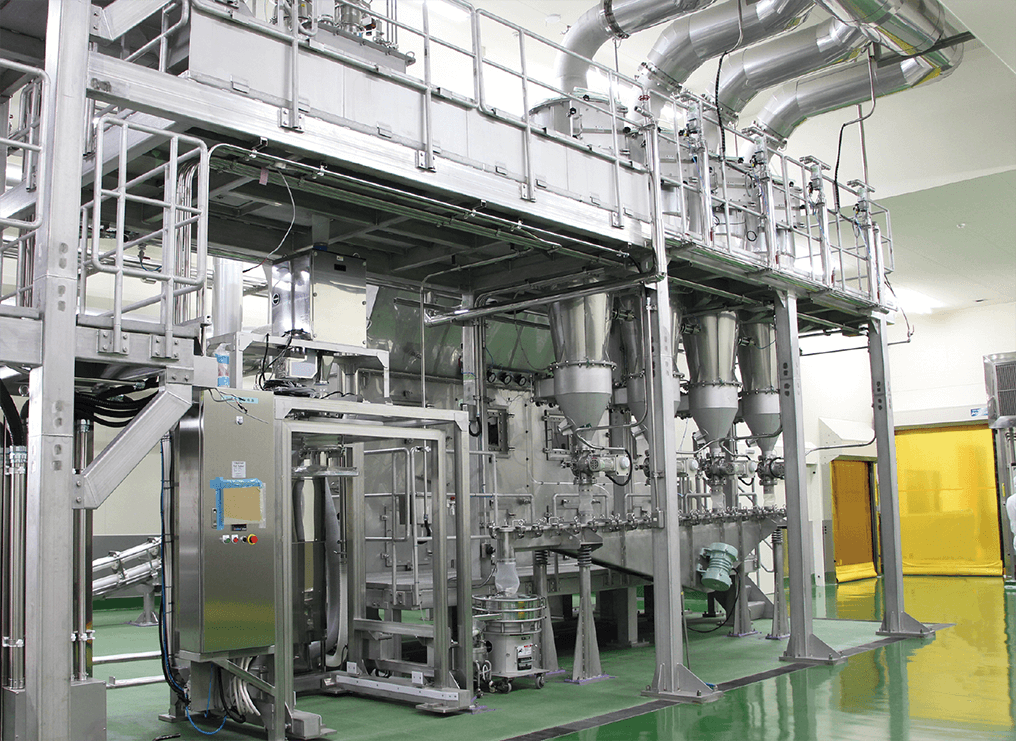

We have the concept of not being confined to conventional customs or habits, and challenge to create new technology for production line.

In particular, by promoting the automation and introduction of robots in every single production line, we aim to improve effciency thoroughly, improve productivity, and deliver safe and high-quality products to our customers.

Acquired certification of international standard "FSSC22000"

We constantly set high targets and are implementing continuous improvements

We acquired the certification of quality management system ISO 9001 in 2005 as we tried to improve the quality of product and have been manufacturing the products with trust and safety under environment friendly machinery and equipment since then.

In addition, in order to reach the global standard of food safety, at the Kanto Factory (including the Kanto No.2 Factory) in 2018, at the Okayama Factory in 2019, we got certification of "FSSC 22000" which is international standard of food safety management system at Okayama Factory.

We will continue to strive to constantly improve by setting high targets all the time.

Regarding Environmental conservation and protection

We acknowledge that our own business activities affect the environment of the Asahigawa River, where the Okayama Factory is located amid abundant nature, and the Nakagawa River, where the Kanto Factory and the Kanto No.2 Factory are located and have acquired the certification of environmental management system ISO14001 since 2000.

Each factory carries out total environmental management, such as CO2 reduction, energy saving, resource saving, effluent reduction, recycling efforts, simplification of containers and packaging, introduction of wastewater treatment equipment to prevent water pollution, and local cleaning project.